Global Sourcing and Supply Chain Management

As manufacturers are growing global, there is an increase in the trend to source from India. We have identified this need and have set up a well-established supplier ecosystem with expertise in various manufacturing processes. We are a global sourcing hub of tailor made parts and high precision components. We follow a well-defined strategy and a meticulous plan to identify the right set of vendors and develop them to become your manufacturing partners.

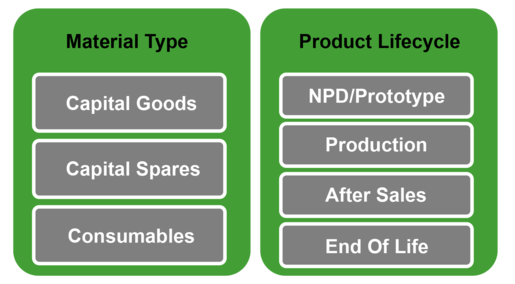

We source different types of precision components like critical spares and consumables and capital goods. Our sourcing strategy is tailor-made to the different stages of product development lifecycle. Be it new product development, prototyping, production, after-sales or end of life sourcing needs, our team of experts and qualified vendors are always willing to go that extra mile and deliver the right part at the right price and right time.

It is important to ensure the quality of parts delivered by the vendors throughout the project duration. We follow standard manufacturing process and assist the vendors to deliver the parts with required quality. We also visit the supplier’s facilities regularly and perform quality checks on the components manufactured.

Sourcing is incomplete without a robust supply chain management. We have devised effective warehousing and logistics processes which helps us to provide our customer with cost effective and timely deliveries.

Our clients do benefit from us in terms of:

- Well established supplier ecosystem

- Well equipped infrastructure with high precision measuring instruments

- Experience with varied manufacturing processes

- Experience in supplying precision components to European machine manufacturers

- Stringent quality assurance processes

Vendor development

We take the complete ownership of vendor development. Our process starts typically with understanding our client’s sourcing objective, strategy, product development stage and sourcing material.

We then identify the right set of vendors and carry out the RFQ process followed by negotiation and finalization. We also undertake periodic quality assurance and audits to ensure the quality standards of the manufactured components.

Our vendor ecosystem is equipped to manufacture parts from different raw material types such as carbon steel, chromium brass, bronze, PVC, POM, teflon and so on.

Some of the components that we can supply include bearing housings, flanges, threaded pins, tailor-made precision components, sheet metal and fabrication parts, sub assembly and so on.

Our activities include:

• Vendor identification

• RFQ process

• Costing and negotiations

• Quality assurance

• Inspection

• Audits

• Training

Manufacturing

We undertake a host of manufacturing support processes such as machining, casting, forging and sheet metal operations. Every process requires domain know-how and meticulous planning for optimum production quality and timely delivery. We plan the right type of manufacturing processes depending on the desired results. Our vendors are equipped with well-established manufacturing infrastructure where we can undertake manufacturing of all types of precision components.

Typical process followed is as below:

Job card preparation, sample manufacturing, 100% inspection of first job before actual production, random sampling inspection at vendors end to ensure that the parts meet the set quality expectations. For critical component- the CNC programming is simulated with appropriate software’s.

We have achieved accuracy as high as 5µ. Over 2000 varieties of components have been developed.

We conduct frequent audit at our vendors facility to ensure compliance to our manufacturing standards including safety norms.

Our core competence in manufacturing includes:

- Manufacturing and supply of high precision components

- Tooling / fixture design and manufacturing

- Specialization in machining, casting, forging and sheet metal

- Specialized surface treatment or coatings such as electroless nickel plating, anodizing, hard anodizing etc.

- Hardening processes such as induction hardening, case hardening, nitriding, vaccum hardening etc.

Supply Chain Management

For timely and cost effective delivery of raw materials and end products to multiple stakeholders, we have developed robust logistics and warehousing solutions. This also includes effective packaging and delivery solutions to meet our customer’s specialized requirements.

We have tie-ups with reputed international freight forwarders and third party logistics partners for hassle free delivery of components to our customers. We deliver parts to our customer’s on-time at their door-steps; this has helped us to align with the just-in-time procurement strategy of our customers.

Our activities include:

- Material management

- Packaging

- Logistics

- Warehousing